|

High-end and tool steels

We use a

sequence of CBN wheels of progressive grits to edge your premium blade,

followed by rock-hard felt or paper wheels loaded with fine diamonds, and thanks

to all wheels having similar diameter, and precise angle control

as the blade is worked on progressive grits and honed, we get crisp

bevels and an exceptional hair-whittling edge.

See our research on Sharpening high vanadium knives >>

Read chapter on sharpening high-end knives in our Knife Deburring book >>

Bevels are

checked with a loupe each time before moving to the next step.

Edge apex sharpness

(or rather keenness) is 0.025-0.05 micron - sharper than safety razors, tested and BESS

certified.

Though we

have polished the inner side of the zinc clamps to make sure no scratches

are left on your blades, high end blades are additionally protected with

a tough cloth tape.

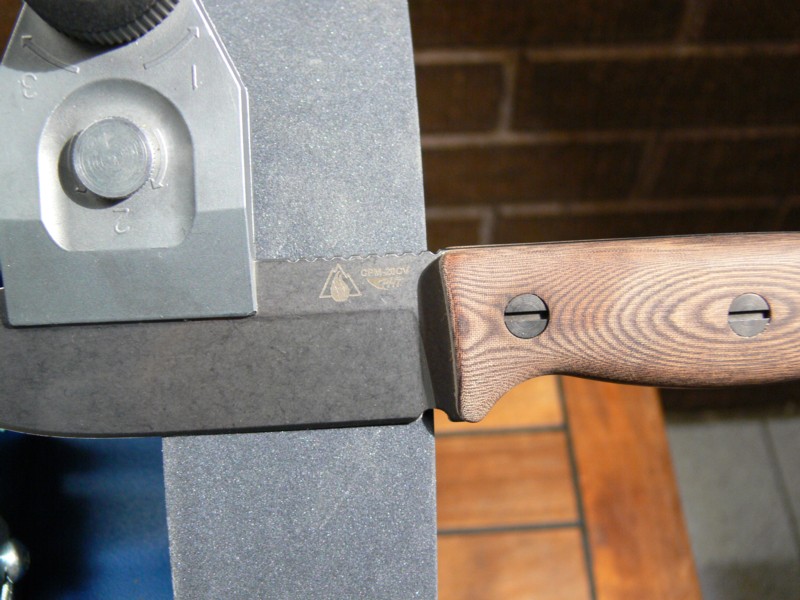

Tormek

knife jig out of the box (right) compared to ours.

Protect the

blade from scratches at the site of clamping with a cloth tape.

Measure the

existing edge angle with a laser protractor, if ordered to reproduce.

(Our

default is 13 degrees per side for high-end wear resistant knife steels.)

Clamp in a jig

matching the blade thickness.

Set the

grinding angle using our computer software.

Grind the bevel

on a Silicon Carbide wheel SB grit 220, or a CBN wheel grit 160 or 200.

Continue on

a 10” CBN wheel, grit 400 or 600.

Set the edge (apex) on

a 10” CBN wheel, grit 1000.

Read more>>

High volume of wear-resistant carbides requires a polishing progression of 10-micron - 5-micron - 2.5-micron diamonds. As you can see on the photo, we have 2 half-speed grinders with paper wheel supports, but you can use a single grinder/buffer and change the wheels as you go.

Slots in the wheel cool the blade like a fan as it is honed.

Polishing on the 10-micron diamonds is done at the edge angle, 2-4 passes alternating sides, till the burr is near gone.

Polishing on the 5-mircon and 2.5-micron diamonds is done at a little less angle to spare the very apex, we set the PW supports at 0.1 degree less than the edge angle, and give the blade 2 passes each side on each wheel.

De-root the burr and remove wire edge on a 10" rock-hard felt wheel with 1-micron diamonds at a higher angle using our Frontal Vertical Base. See Knife Deburring book for technicalities.

Give the blade 3 slow passes alternating sides with little-to-no pressure.

Finish with

controlled-angle honing on a 10” slotted paper wheel with a mix of 0.25 micron diamonds and Chromium Oxide at the exact edge angle.

Test

sharpness.

At Knife Grinders we check edge by two devices used together: a BESS PT50 edge sharpness tester plus Razor-Edge edge tester.

While the BESS sharpness tester is spot sampling, the Razor-Edge edge tester checks condition along the length of the edge, and used together, they give pretty comprehensive idea of the whole edge quality, and this tandem is our QA method at the end of each sharpening session.

|

Measure

the existing edge angle with laser protractor, if ordered to reproduce.

(Our default is 13 degrees per side for wear-resistant knives.)

|

|

|

Clamp in

a jig matching the blade thickness.

Read more>>

|

|

|

Set the

grinding angle using our computer software.

Read more>>

|

Jig-Support-Wheel

relations are calculated by computer scripts, and set with 0.1 degree

accuracy.

|

|

Grind the edge bevel on a Silicon Carbide wheel SB grit 220, or a CBN wheel grit 160 or 200.

|

|

|

Continue

on a 10” CBN wheel, grit 400 or 600.

Read more>>

|

|

|

Set the edge (apex)

on a 10” CBN wheel, grit 1000.

|

|

|

High volume of wear-resistant carbides requires a polishing progression of 10-micron - 5-micron - 2.5-micron diamonds. As you can see on the photo, we have 2 half-speed grinders with paper wheel supports, but you can use a single grinder/buffer and change the wheels as you go.

Slots in the wheel cool the blade like a fan as it is honed.

Polishing on the 10-micron diamonds is done at the edge angle, 2-4 passes alternating sides, till the burr is near gone.

Polishing on the 5-mircon and 2.5-micron diamonds is done at a little less angle to spare the very apex, we set the PW supports at 0.1 degree less than the edge angle, and give the blade 2 passes each side on each wheel.

Read more>>

|

|

|

De-root the burr and remove wire edge on a 10" rock-hard felt wheel with 1-micron diamonds at a higher angle using our Frontal Vertical Base. See Knife Deburring book for technicalities.

Give the blade 3 slow passes alternating sides with little-to-no pressure.

|

|

|

Finish

with controlled-angle honing on a 10” slotted paper wheel with a mix of 0.25 micron diamonds and Chromium Oxide at the exact edge angle.

|

|

|

Test

sharpness

Read

more>>

|

|

|