|

Ranking knife brands by CATRA

Quality & Service

Industrial assessment

Knife rental

Proprietary 7-Carcasses Edge

Equipment

we use >

Sharpening procedures

Guarantee

Sharpening resources

Sharpness testing

Edge stability testing

Sharpening Shop

Celebrities, press, exhibitions

Our industrial customers

Contact

Feedback

|

We've

invested heavily in the most efficient knife sharpening equipment.

Cost of equipment has never been a restraint to us, the edge quality is the

only consideration we take into account.

To see the equipment in use, you can check our Sharpening Procedures

section.

|

Precision control equipment

|

|

Laser protractor

to control edge angle;

BESS sharpness tester;

AngleCube;

Edge tester;

Microscope and loupe.

|

|

|

Laser protractor.

|

|

|

AngleMaster

for blades not fitting the laser protractor.

|

|

|

BESS certified

sharpness tester.

Read

more>>

|

|

|

Razor-Edge Edge Tester

for blades not fitting the BESS sharpness tester, but not limited to that.

While the BESS sharpness tester is spot sampling, the Edge Tester checks the whole length of the edge, and used together, they give pretty comprehensive idea of the edge condition.

|

|

|

Laser

guide.

Used in Convex, Concave and Recurve blade sharpening.

|

|

|

Sharpening equipment

|

|

Volume sharpening suite.

Capacity 200-300 knives per shift per operator.

Read more>>

|

|

|

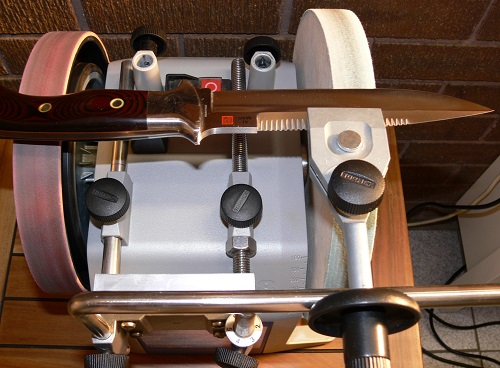

Tormek

slow speed wet sharpener equipped with an extra-long universal support

US400, and frontal vertical base for sharpening away from the wheel and

angle-controlled honing on felt and leather wheels.

We use T7

and T8 Tormek machines.

Grinding and honing angle is controlled with our computer software.

|

|

|

Grinding

wheels for carbon steels, also used for mainstream stainless steels:

Aluminium

Oxide SG-250;

10 Japanese #800;

10 Japanese #4000;

Japanese #5000 SJ-250.

We order Japanese wheels for ourselves directly from Japan.

It goes without

saying that our stones are trued square and round at all times.

|

|

|

CBN wheels for stainless, high-carbon and hard-alloy steels:

10 CBN

square-edge wheels for regular blades, and

10 CBN

round-edge wheels for sharpening concave and curved blades;

grits

#80, #160, #400, #700 and #1000.

Read

more>>

|

|

|

Tormek-compatible

10 rock-hard felt wheels loaded with diamonds for fine sharpening, honing and deburring.

We designed a frontal vertical base for honing on felt wheels and

Tormek leather wheel.

Read more about our felt wheels >>

|

|

|

For sharpening serrations on Tormek, we designed a double-taper felt wheel.

Read more about our double-taper felt wheel for serrations >>

|

|

|

Frontal vertical

base for edge-trailing sharpening of knives, cleavers and wide blades, and angle-controlled honing on

leather and felt wheels.

Grinding and honing angle is controlled with our computer software.

Read more>>

|

|

|

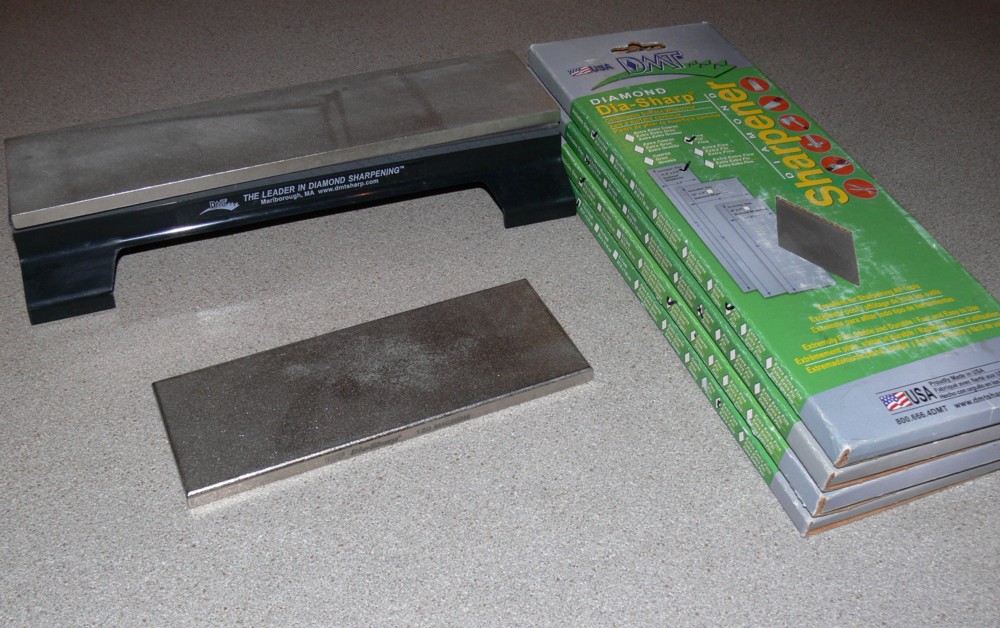

Bench stones.

Diamond plates, Japanese whetstones, natural and ceramic bench stones

of various grits.

|

|

|

DMT Diamond

plates.

|

|

|

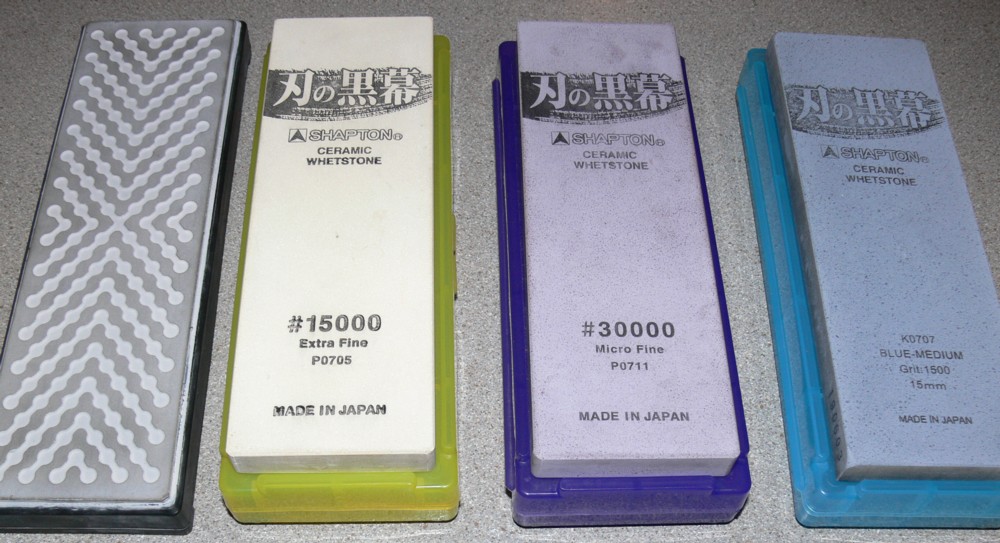

Japanese whetstones.

|

|

|

Finest

Shapton whetstones.

|

|

|

Natural

bench stones:

Charnley

Forest;

Beryl;

Translucent

Hard Arkansas;

Welsh

Slate Dragon Tongue.

|

|

|

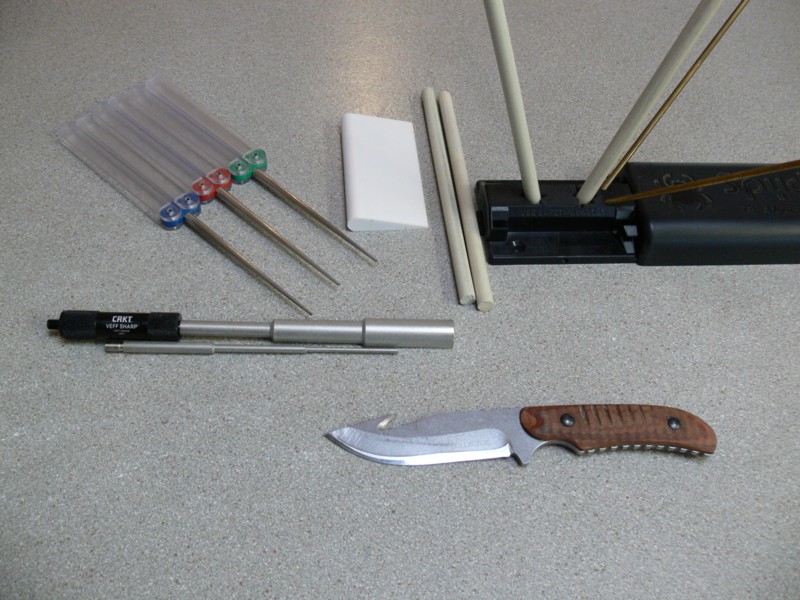

Equipment

to restore serrations and concavities.

Dremel

with diamond wheels;

DMT Diafold Serrated Knife Sharpener, diamond coated;

VEFF

Sharp, diamond coated;

Spyderco ceramic slip stone;

Spyderco

Tri-Angle Sharpmaker with tri-angle stones and ceramic rods of various

grits.

|

|

|

Radial

bristle disks.

We use them in restoration of the serrations.

Sharpening serrations had

been a long quest for us - the serrated blade had been showing obstinate

resistance to all our approaches, till we finally found a solution that

delivers fine shaving edge in every serration, not smoothing away the peaks.

Radial

bristle disks are made of Cubitron and Aluminum Oxide grains embedded

throughout the flexible plastic bristles.

Grits

#80, #120, #220, #400, #600, #1000, #2500.

As the radial

bristle disk grinds, it also works as a cooling fan, making it possible

to use it with Dremel on finest edges without risk of overheating.

|

|

|

Equipment

to sharpen gut hooks.

|

|

|

Smaller

scissors are sharpened with Spyderco Sharpmaker.

|

|

|

A

linisher to fix broken tips, straighten worn out edge, and reduce

bolsters.

We use coarse belts that generate less heat.

|

|

|

Honing and stropping equipment

|

|

Honing

station for angle-controlled honing.

RazorSharp paper wheels and flint-hard felt wheels with various grit

diamonds, run on slow half-speed buffers.

Honing angle is controlled with our supports and computer software.

How to Set Up Paper Wheels >>

Video >>

|

|

|

Diamond

paste and sprays of various grit.

|

|

|

Kangaroo tail hanging strop.

Kangaroo tail is renown for the highest tensile strength of all animal leathers, making it an exceptional hanging strop.

Kangaroo tail is different to the skin: the kangaroo skin is smooth, while the tail has a palpable cross-texture; the difference is the same as between the human skin and sole. Knives stropped on the kangaroo tail stay sharp for longer than those stropped on its skin - this is sort of a factual knowledge in Australia.

Video:

Kangaroo Tail Strop Effect on Sharpness >>

Research and stropping technique:

Use of Hanging Strop in Knife Sharpening and Maintenance

More interesting facts >>

|

|

|

8 tapered

flint-hard felt split laps loaded with diamonds for honing concave and

Recurve blades.

|

|

|

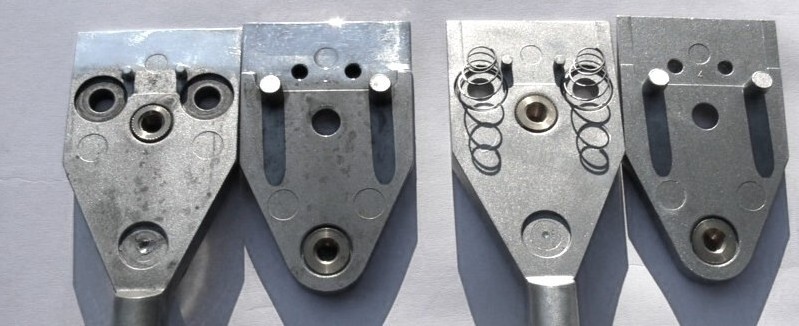

Knife jigs matching blade thickness

|

|

Jigs

matching the blade thickness provide for symmetric bevels of even height.

Jig #1 -

up to 3mm thick knives;

Jig #2 -

for 3-4mm thick knives;

Jig #3 -

for 4-5mm thick knives;

Jig #4 -

for 5-7mm thick knives.

Read

more>>

|

|

Tormek

knife jig out of the box (right) compared to ours.

|

We have

polished the inner side of the zinc clamps to make sure no scratches

are left on your blades.

|

|

|

Simple

but nonetheless accurate jig projection measuring/setting block.

Its main function is to align the knife edge parallel to the plane of the jig adjustable stop; the 2nd function is to measure the jig projection for use with our software.

Having the knife edge (not the spine) strictly in parallel to the jig adjustable stop is a prerequisite for uniform apexing and getting ultimate sharpness.

See how to use >>

Read how to make it on the Tormek forum >>

|

|

|

|

|

|

Right jig for each blade

|

|

We have

all jigs ever manufactured by Tormek for edged blades, not to mention our homemade.

Jigs for

long and small knives, scissors, axe, planer blade etc etc.

|

|

|

Pivot collar used on the knife jig for sharpening convex, concave and Recurve blades, and regular blades with steep tips.

Unique design, made on special order.

Read

more>>

|

|

|

Our Tormeks grind faster by 40%

|

|

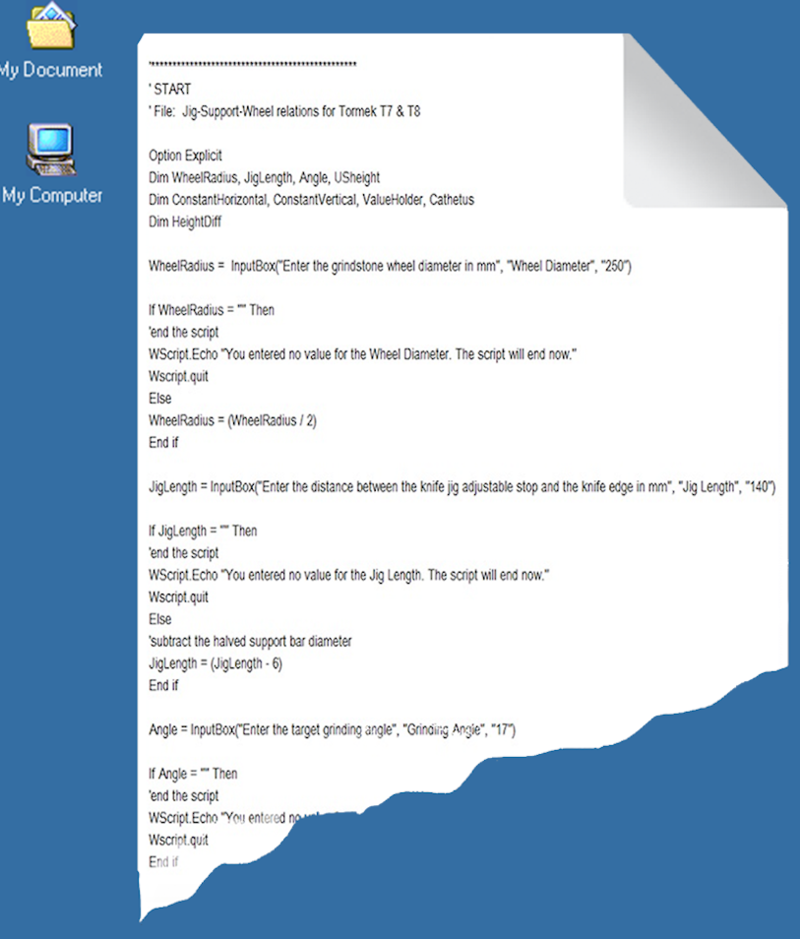

Computer software to set exact grinding/honing angle

|

|

We developed

computer software for Tormek, other wet grinders and paper wheels.

Quicker than any other method, and more accurate.

Our computer software is used to:

- grind exact edge angle;

- match grinding wheels of different diameter;

- match the ground angle with the honing angle on Tormek leather wheel, using our Frontal Vertical Base.

Thanks to this software we now have every knife edge apex near 0.1 micron, true razor.

Time-wise

it is quicker than any other method.

Read

more>>

Video>>

|

|

|