|

Ranking knife brands by CATRA

Quality & Service

Industrial assessment

Knife rental

Proprietary 7-Carcasses Edge

Equipment we use

Sharpening procedures

Guarantee

Sharpening resources

Sharpness testing

Edge stability testing

Sharpening Shop >

Celebrities, press, exhibitions

Our industrial customers

Contact

Feedback

|

CBN Wheels for Tormek and alike slow grinders

Square Edge

Round Edge CBN Wheel for both curved and straight blades

|

|

|

|

Dual-fit CBN wheels run both on common grinders and slow wet grinders like Tormek etc

|

CBN wheels are the single biggest advance in sharpening in a very long time

|

Our all-aluminium

CBN wheels run with tap water on all slow wet grinders with 12 mm shaft that take 250 mm wheel:

Tormek, Scheppach, Jet, Record, Grizzly, Triton, Saber, WEN, Holzmann NTS 250PRO etc.

Suitable for all knife and tool steels.

Only our CBN wheels can be run with common running water from your house or workshop tap thanks to the special embedding technology. Note that if you run CBN wheels of other makers with water, the CBN coating may detach from their wheel base.

Cubic boron

nitride (CBN) properties include extreme hardness, stability under heat,

and superior chemical resistance.

Cubic boron

nitride is the second-hardest known material on the planet (after

diamonds), but has higher heat and impact resistance than diamonds, and

therefore CBN is preferred over diamond in industrial applications.

CBN perfects

in sharpening hard alloy, tool and high-speed steels, as well as ceramic blades, and has

advantage over conventional abrasives in sharpening carbon and mainstream stainless

steels, delivering a superior edge compared to the stone wheel.

CBN superabrasives remove material in a unique way; due to their super hardness the whole process is quite similar to the milling operation, while conventional abrasives like aluminium-oxide and silicon-carbide have more similarity with sanding. Thanks to that the CBN wheel produces smaller burr and sharper edge apex as compared to aluminium oxide and silicon carbide. Comparison between conventional abrasives (aluminium oxide or silicon carbide) and CBN cubic boron nitride reveals that for conventional abrasives burrs tend to be of a long and thin shape whereas for superabrasives the burrs tend to be relatively small and thick.

Grinding on

the 250 mm wheel gives a near flat edge, with very little concavity; the CBN

layer on the sides of the wheel allows for completely flat grind.

CBN vs DIAMONDS

Synthetic diamonds are cheaper than CBN crystals.

Compared to diamonds, the CBN crystals have better crushing, thermal and chemical resistance.

Under workload, the CBN crystals gradually chip maintaining sharp facets, while diamond crystals macro-fracture, forming flats on the wheel. Compare the following SEM of the electroplated diamond and CBN wear:

Since diamonds macro-fracture from pressure, Tormek instructions on their diamond wheel stress that the sharpening pressure should be "very light". CBN wheels withstand the pressure better and you can grind with firm pressure, but not overly hard. When CBN micro-chip the newly formed facets sustain their cutting ability.

Because of this difference, CBN is preferred for grinding, while diamonds for honing - and this is how we use them in our workshop. We bevel and set edge on CBN wheels, then hone on paper/felt wheels with diamonds.

For example, your 5-micron diamond honing wheel, with use will also have, along with the nominated 5-micron crystals, a fraction of smaller 3-micron and 1-micron diamonds from the crushed original crystals, eventually giving a better polished finish.

Our CBN wheels are perfectly balanced, dead flat, and have better tolerance

specifications than others’.

SPECIFICATIONS

CBN grinding wheel for Tormek

|

Parameter

|

Knife Grinders

CBN Wheel

|

Tormek

Diamond Wheel

|

Others

CBN Wheels

|

|

Can be run

with tap water at the specified RPM?

|

Yes

|

No

|

No

|

|

Wheel

Material

|

Aluminium Grade 6061

|

Steel

|

Aluminium or steel

|

|

Wheel

Diameter, mm

|

250 +0.2-0.5

by the grit #

|

250.1

|

254 +/- 0.1

|

|

Arbor Hole,

mm the tighter the bore - the rounder the wheel runs

|

12.04 +/- 0.01

|

12.04 - 12.06

|

12.04 - 12.08

|

|

Wheel

Width, mm

|

50 +0.1-0.4

by the grit #

|

50

|

50.8 +/- 0.1

|

|

Side Face, mm

|

30*

|

52

|

25

|

|

Side Face

on both inner and outer wheel sides

|

Yes

|

Outer only

|

Yes

|

|

Wheel Machined

Surface Flatness, tolerance mm

|

+/- 0.015

|

Unpublished

|

Unpublished

|

|

Wheel Axial

and Radial Tolerance, mm

|

+/- 0.02

|

0.15

|

Unpublished

|

|

CBN Layer Surface

Evenness, tolerance mm

|

0.020

|

0.1

|

Unpublished

|

|

CBN coating thickness, mm

|

up to 0.22

|

Unpublished

|

Unpublished

|

|

Nominal RPM range

|

wet up to 250;

dry up to 3500

|

up to 150

|

90-100

|

|

Available

grits

|

(ISO) 80, 160, 400, 700, 1000

|

(FEPA) 360, 600, 1200

|

(ISO) 200, 400, 600, 800, 1000, 1200

|

|

Weight, kg

|

4.3

|

4

|

~ 4

|

* Tormek water trough filled to the MAX WATER LEVEL mark covers 30mm of the side of the wheel, and this is the reason the CBN side face is 30mm in our wheels. If we made the side face in our wheels over 30mm, then part-wet, part-dry grinding would result in an uneven grind.

Our dual-fit CBN grinding wheel for common grinders and slow wet

grinders like Tormek, Scheppach, Jet, Record, Triton, WEN, Holzmann NTS 250PRO,

Grizzly etc.

|

Parameter

|

Knife Grinders dual-fit CBN Wheel

|

|

Can be run with tap water

at the specified RPM?

|

Yes

|

|

Wheel Material

|

Aluminium Grade 6061

|

|

Wheel Diameter, mm

|

250 +0.2-0.5

the +0.2-0.5 variation is by the grit #

|

|

Arbor Hole

|

Dual-fit 5/8"(16mm) & 12 mm

|

|

Wheel Width, mm

|

30 +0.1-0.4

the +0.1-0.4 variation is by the grit #

|

|

Wheel Machined Surface

Flatness, tolerance mm

|

+/- 0.015

|

|

Wheel Axial and Radial

Tolerance, mm

|

+/- 0.02

|

|

Nominal RPM range

|

wet up to 250;

dry up to 3800

|

|

Weight, kg

|

2.2

|

OUR CBN WHEELS GRIT

|

Knife Grinders Wheel Grit #

|

Corresponding Grit by Standard

|

|

Grit #

on our wheel

|

CBN mesh size

micron

|

JIS

(Japan)

|

FEPA

(Europe)

|

|

80

|

150/180

|

80

|

80

|

|

160

|

90/105

|

120

|

150

|

|

400

|

38/45

|

400

|

360

|

|

1000

|

13/16

|

800

|

1200

|

Selection of grits is based on the years of sharpening in our workshop.

We experimented grinding knife bevels with coarse CBN wheels on Tormek, grits from #80 to #360, and found out that the #160 grinds way faster than #200 and over, not shredding the knife edge as do grits under #100 - the #160 has become our choice for beveling.

We intentionally omit the grit #600, as per our experience, the grit #600 is too slow for grinding bevels, and too coarse for edge-setting in higher end and folding/pocket knives - in knife sharpening #600 is the grit you do better without.

DIRECTION OF ROTATION

At high RPM work with the wheel rotation to prolong the CBN wheel life span.

On slow wet grinders like Tormek direction of rotation does not effect the lifespan, and we grind chiefly into the wheel as this creates a smaller burr that is easier to remove.

SPEED OF GRINDING

Compared to stone wheels, at low RPM the CBN and diamond wheels grind a little slower the mainstream stainless knife steels, but faster the hard alloy steels and high HRC carbon steels. Furthermore, because pressure on the blade ground on a CBN/diamond wheel must be less than on a stone wheel, we have to use a coarser CBN grit for the same grinding speed as compared to the stone wheel.

WHICH

CBN WHEEL IS FOR YOU

Woodworking tools: #80 or #160 and #400 wheel. For fine carving chisels also #1000.

Having ground a woodworking tool on the CBN #400, finish on finer bench stones.

For knife

sharpening by slow wet grinding:

- kitchen and butcher knives: #80 followed by #400 - then deburring;

- high end knives: bevel on #160 and #400, set the edge apex on #1000 wheel - then honing &

deburring;

- folding and pocket knives: #400 wheel followed by #1000 - then

honing & deburring.

High RPM CBN sharpening is for mainstream kitchen, butcher and boning knives, and is done on a pair of CBN wheels #160 and #400. The #400 is the finest grit these knives need. At meat plants they sharpen knives on #400, and meat plants have a long history of streamlining the sharpening process.

High-end kitchen knives we re-profile to a lower angle on our CBN wheels run on a grinder, and complete grinding on Tormek.

Sharpen common knives on our CBN wheels run on a half-speed grinder, while folding and high-end knives on the same CBN wheels but run on Tormek or alike slow wet grinder.

If you often repair dents, reprofile bevels, or do first-time sharpening for knifemakers, you will benefit from the extra coarse #80 wheel for quick steel removal.

When grinding on slow Tormek etc, because pressure on the blade ground on a CBN/diamond wheel must be less than on a stone wheel, we have to use a coarser CBN grit for the same grinding speed. Where we sharpen regularly, e.g. for a commercial kitchen, the CBN #160 works OK, however sharpening dull knives from irregular customers we need to start grinding on the CBN #80. On the other hand, where the knife is under such a workload that has to be re-sharpened daily, a single #400 CBN wheel can do.

Unlike with the stone wheels, where you can go from grit #220 to #1000, on CBN wheels you should follow a more gradual grit progression, i.e. #160 - #400 - #1000; or #80 - #400 - #1000. Going from the Tormek stock stone wheel #220 or CBN #80/160 wheel straight to the CBN wheel #1000 shortens lifetime of the CBN wheel #1000.

Square Edge CBN Wheel

Our Square Edge CBN Wheels grit range: #80, #160, #400, #1000.

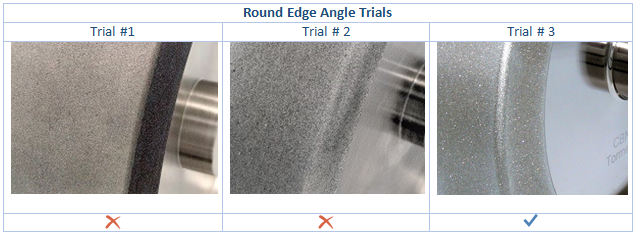

Round Edge CBN Wheel

Our Round Edge CBN Wheels grit range: #400, #700, #1000.

For sharpening concave and recurve (S-edge) blades, you will need two Round Edge CBN Wheels: bevel on #400, and set edge on #1000.

We do not use coarser Round Edge CBN Wheels, because the higher pressure per point on the corners makes coarser wheels less suitable for sharpening concavities in curved knives.

We use the CBN #700 only to sharpen folding knives with a curved blade, that are too delicate to grind curves on the #400.

We've experimented with round-edge CBN wheels made to order, to find out the minimal wheel edge radius that works well for sharpening curved blades.

Our Round Edge wheels are designed with little radius on the corners, and the wheel is dead-flat between its radiused edges, so that the vast majority of regular "straight" knives can be sharpened on them as well, making them the most versatile in knife sharpening.

Recommended minimal kit of our wheels, covering the majority of knife shapes:

Square Edge CBN Wheel #160 (coarse) and/or #80 (extra coarse);

Round Edge CBN Wheel #400 (medium).

If you often repair dents in abused knives, or re-grind bevels in neglected knives - add the Square Edge CBN Wheel #80 or take it instead of the #160.

Mainstream knives can all have the edge set on #400 and moved straight to deburring. Lower quality knives MUST be set on #400, not #1000. When I do assessments at meat plants, they all set edge on #400 and deburr.

However, with the higher quality knives you will give the edge better performance and longer retention, if you set the edge on #1000.

As a coarse wheel you can use your stone wheel that comes with the machine, e.g. Tormek SG #220 wheel graded coarse, and continue on CBN wheel #400 followed by #1000, but you cannot do with a single CBN #1000 wheel. As explained above, going from the stock stone wheel #220 straight to the CBN wheel #1000 shortens lifetime of the CBN wheel #1000.

Notes on using our extra coarse #80 CBN wheel:

Our #80 CBN wheel is the coarsest available in the world for Tormek. We've developed the #80 for beveling newly made knives, sharpening grossly neglected very dull and chipped blades, and re-profiling bevels to a lower angle. Using #80 susbtantially reduces time in these time-consuming sharpening operations.

Never apex brittle steels on #80, because the deep scratches going to the apex are like flaws along which chipping may develop when the knife is put to use. So when we grind bevels with the #80, short of the apex we change to our #160 or #400 CBN wheel. In other words, we will not raise a burr on #80, we will change to a finer grit wheel and grind to the apex and raise the burr on it. "Brittle steels" include steels prone to chipping like Shun and VG10, "supersteels", tool steels, steels in the negative burr group, blades hardened to HRC60+ etc.

Mainstream knives can be apexed with #80 w/o issues. From #80 we can go straight to #400, it is not mandatory to have the #160 in-between.

We also use the CBN #80 to narrow worn knives to prolong their life. Sharpen at 10 degrees per side on the #80 wheel, then a few passes at the same angle on a #400 wheel to remove the scratches, and buff. Then sharpen at your target edge angle on the #400 wheel.

There are certain knives that we do not grind on #80 at all, because the blade is too delicate, like pocket knives, folding knives, flexible and narrow knives (e.g. filleting, boning). These knives we bevel on #160, or even on #400.

While grinding on the #400 wheel after the #160 we usually do only 1 pass each side, but after the #80 wheel we do 2-4 passes alternaring sides on #400 - to grind away the scratches left by #80.

Notes on using our ultra fine #1000 CBN wheel:

Sharpeners new to CBN and diamond wheels tend to think of the ultra fine CBN/diamond #1000-1200 as similar to the finely graded stone wheel, but they are not. Unlike the stone wheel, the ultra fine CBN/diamond will wear off prematurely if used after a coarse wheel.

The #1000 wheel is not for grinding, it is for minimising the burr, setting the edge apex and delicate honing of the bevels. Must be used in the very end of grinding and only after the #400 (or finer), typically 1-2 passes each side with little pressure. Please note that thickness of the #1000 CBN coating is the least of all wheels, and if we press hard we will wear it off quickly.

Normal wear shows up on the wheel corners first, but the wheel still has a long lifespan if not overused.

MOUNTING INSTRUCTIONS

The central hub of the wheel is longer on the side facing your machine - mount this side first on the machine shaft; the opposite outer side of the wheel has our KG LOGO and marking.

The arbor hole in CBN wheels is smaller than in stone wheels by design. Because you cannot true the CBN wheel, the bore must be as close to the shaft diameter as practical; if we made the hole any wider, the wheel would sit on the shaft off-center and run as if it is out of round.

Because of that tight fit, firstly, maintain the hole and the shaft clean, and secondly, do not let the wheel sit on the shaft for long - dismount the wheel at the end of the working day so that it won't get stuck.

Before mounting our CBN wheel after a stone wheel, clean the shaft of your Tormek with some lubricating cleaner, like WD-40.

When your CBN wheels are shipped in cold season, let them warm up after being in the cold before mounting on your Tormek. In winter, it may take over 24 hours in the room for the arbor hole in the CBN wheel to widen back to the normal diameter.

USAGE

Our CBN wheels can

be run with tap water or metal-working fluids, or dry.

Handle with

care.

CBN crystals are embedded in nickel, electroplated onto the aluminium wheel base, and

this nickel-CBN layer does not withstand hard impact. We have noticed that hits against the Universal Support bar and shaft of your Tormek

when removing the wheel are common with the beginners.

Dents on your wheel from inaccurate handling are not subject to Warranty

replacement.

The arbor hole in CBN wheels is smaller than in stone wheels by design. Because of that tight fit, maintain the hole and the shaft clean, and take the wheel off after sharpening. If needed, clean the shaft of your machine with some lubricating cleaner e.g. WD-40.

Do not leave the CBN wheel on the machine shaft overnight, or it may get stuck.

Sharpen with

a low pressure.

Maintain firm contact of the blade with the wheel, but never press hard, as

excessive pressure may strip off the CBN

crystals. The easiest way to control pressure is by watching nailbeds of

your fingers on the blade – they should remain pink; when you press too

hard, the rim of your nailbeds turns white because of blocked blood flow in

the nailbed capillaries.

CBN coating wear from heavy pressure is not subject to

Warranty replacement.

Never grind

metal other than hardened knife and tool steel on the CBN wheel (e.g. iron, galvanized steel, zinc-plated metals, aluminium, brass etc).

Never grind unhardened steel like knife blanks etc on the CBN wheel – the ground soft metal will

plug (glaze) the CBN.

Glazed CBN wheel surface is not subject to Warranty replacement.

Never grind on

CBN scissors and other blades that require over 45 degrees per side – the

higher the grinding angle, the more CBN crystals are stripped off, especially when grinding into the wheel.

For the same reason do not repair broken tip or dents by pressing the blade perpendicular to the CBN wheel.

When grinding the tip of your blade, take care not to poke it into the

wheel under a high angle, as the pointed tip may strip off CBN crystals.

Meat plants often blunt the tip for safety - do not do it on our CBN wheels.

CBN coating stripped off the wheel surface is not subject to Warranty replacement.

Do not leave the wheel sitting idle in water – drop the water trough as soon as you

stop grinding, and let the wheel dry after sharpening.

Rust on the wheel is not subject to Warranty replacement.

BREAKING IN

We break in a new CBN wheel by sharpening mainstream stainless steel kitchen knives. 1-2 grindings is all needed, and the wheel is ready to use, including for high-end knives. The purpose of grinding first a low value knife on a new CBN wheel is to let any loose crystals go, as when they leave the wheel they may scratch the blade.

If you have experience with diamond plates or wheels, you will see that the CBN grinding wheel behaves differently, it has a shorter "break-in" period.

If you use our software for setting grinding angle, re-measure the wheel diameter after the first 10-20 grindings.

RUST

Our CBN wheels do not rust when run with tap water, however the ground metal deposited on

the wheel does.

Change water in your trough every day and when you see too much of the ground material accummulated on the trough magnet.

The rust from ground metal does not affect the CBN wheel performance, but

if it is aesthetically unpleasant to you, it can be lessened by cleaning

the wheel at the end of sharpening with a tooth brush and kerosene or turpentine.

(Never use wire brush for cleaning CBN wheels.)

WATER SALTS

Salts in hard water promote rust development as you grind.

If tap water in your location is hard, we recommend to boil it for a few minutes and cool to lower concentration of the dissoved minerals before use for wet grinding.

LIFE

SPAN

CBN wheels definitely outlast diamond wheels thanks to the CBN crystals better resistance to crushing.

Life span of your CBN wheel depends on the sharpening pressure and workload. The CBN layer does wear over years of use, and if a seller tells you that his CBN wheel will last for your lifetime, it is puffery.

Coarse CBN wheels that take the brunt of grinding load, wear sooner.

If you jump grits, e.g. go from the Tormek stock stone wheel #220 or CBN wheel #160 straight to the CBN wheel #1000, the latter will wear sooner, than when you go through the due CBN progression of the #160 - #400 - #1000.

We've noticed 3 distinct phases in the life of a CBN wheel.

Phase 1: The CBN crystals settle in the initial break-in period, and the broken-in wheel cuts somewhat less aggressive than in the very beginning; by the end of grinding you can see in the trough some sediment of CBN crystals chipped off the wheel – this is normal.

Phase 2: Under workload, the CBN crystals gradually micro-chip maintaining sharp facets. Micro-chipping of CBN particles throughout the wheel life progressively increases the topographical density of active grains, which sustains its grinding ability with use. Thanks to that the CBN wheels maintain their cutting ability for a long time.

Phase 3: The CBN wheel gradually takes on a somewhat finer grit with use, e.g. the #160 wheel becomes more like #200-300, the #400 wheel becomes more like #600, and the #1000 more like #1200.

This is another reason why the original grit range of our CBN wheels omits the grit #600, since your #400 wheel will develop that grit with use and eventually you will own it anyway.

Used for

professional sharpening in our workshop, CBN wheels started showing signs of wear in the first year of use, noticeable at the corners of the

wheel, yet they perform well over 3 years as I am writing this; we haven’t

replaced a single wheel because of wear.

To maximize life span of your CBN wheels, do not skip grits and apply enough pressure to maintain firm contact of the blade with the wheel, but not overly hard. Since we cannot control these parameters of your sharpening, we cannot warranty the life span, however by statistics in our workshop, when blades are sharpened with the full grit progression of #160 - #400 - #1000, the nickel-CBN electroplated aluminium wheels last for 4000 knives on average, and are still usable as of a finer grit. (For comparison, Tormek 250mm stone SG wheel that comes with T-8 lasts for 1000 knives on average.)

CBN

WHEEL WARRANTY

We are able to offer our CBN wheels at the lowest price in the market, because warranty claims on our wheels are next to zero thanks to the strict quality control. With so many defects reported on diamond and CBN wheels of other makers, no wonder their warranty replacements are often, and factored into the price raise it by 25-50% compared to ours.

We unconditionally warranty that our wheels will never show defects reported on others' diamond and CBN wheels, such as being not flat, CBN/diamond layer premature wear, bulging, flaking, peeling and detachment, as evident on these videos and photos of defects >>

We inspect each

wheel before shipment, and warranty that:

|

-

|

Your CBN

wheel will be free from defects in workmanship and materials.

|

|

-

|

Your CBN

wheel is round, square and flat within tolerances as per our

specifications.

|

|

-

|

Your CBN

wheel will not warp, twist or run out of round.

|

|

-

|

The CBN

coating has no dents, chips or high spots, and will not detach, peel or crack

under intended use.

|

|

-

|

Replacement or refund is at the sole discretion of the Knife

Grinders.

Prior to shipping your wheel for replacement, please email us the defect

description and photo, to confirm this particular defect is covered by

our Warranty and the wheel is subject to replacement; we may advise you

not to ship us the problem wheel, but rather send you a replacement wheel

straight away.

If unclear from your photos and description, you may need to send the problem wheel to us for inspection. Any wheel being returned for warranty purposes first has to be shipped at the

owner’s expense.

Wheels that meet the Warranty criteria will be, at Knife Grinders' option, either refunded in full, or replaced with all costs

paid by Knife Grinders, and the initial shipping expenses of the

wheel owner compensated.

|

|

-

|

This warranty lasts for one (1) year from the date of original purchase.

|

|

-

|

Warranty is

null and void if the wheels are not used for the purpose in which they

are intended, and as specified above in the USAGE.

|

|

-

|

This Warranty covers only the original buyer and is not transferrable, i.e. if you re-sell our CBN wheel your buyer is not covered.

|

Buy our CBN wheels >

|