|

Knife Grinders are the first in Australia to offer edge stability testing.

Video >>

Structural Edge Tester is a method and device developed by Mike Brubacher Edge On Up for testing edge stability.

In a nutshell, the edge is subjected to controlled rolling, the extent of which is quantified.

This method is different to the CATRA edge retention test. The CATRA testing tests the edge retention to abrasion.

While the Structural Edge Tester (SET) tests stability of the edge to rolling, to the impact at an angle.

|

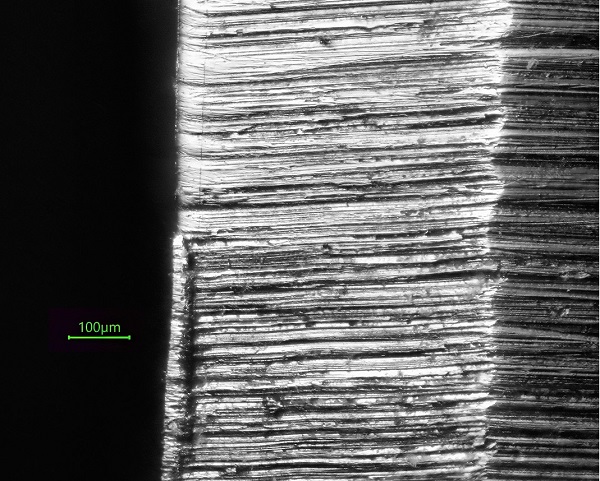

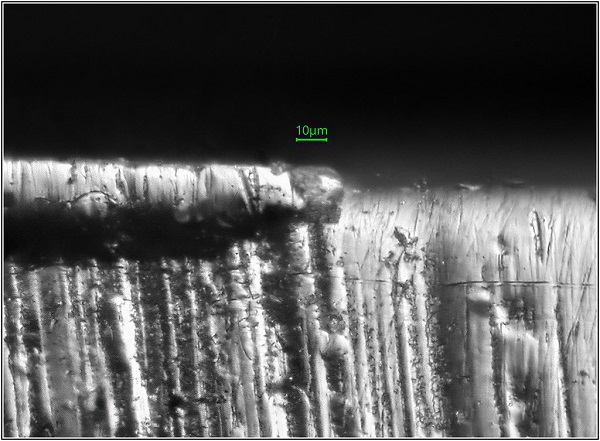

Metallurgical microscopy of the edge after a single roll by the Structural Edge Tester follows.

Sampled is a mainstream knife subjected to 1 rolling cycle.

The upper portion of the micrograph shows an untouched region of the edge apex. The edge apex is lightly convex from honing.

The lower portion of the image shows where the edge has been rolled over. The rolled region has been pushed towards the viewer.

Micrograms by Tony Spielberg

|

Areas of application

Meat/fish processing plants and abattoirs - determine the most robust edge angle for the knives you use.

We’ve proved that the SET method can be used to determine the most robust edge angle for knives used at meat processing plants.

Blades with lower edge stability require higher edge angles.

Knives with the edge angle matching the steel characteristics stay sharp 2 times longer. Sharpening at the best angle for a given knife brand ensures the best edge retention, sharpness and longer life span of the knives, saving plants tens of thousands of dollars a year.

Volume knife users - differentiate a quality knife brand and production batch from inferior, and save money.

Cutting blade and knife manufacturers - detect manufacturing defects caused by a problem steel or non-optimal heat treatment.

Custom knife makers - detect a partially annealed edge.

Knife collectors - counterfeit detection.

Generally, a suspected counterfeit must be physically posted to the manufacturer, with the expenses on the sender - we give a preliminary advice by this testing since quality steels are significantly less susceptible to rolling than inferior steels used in counterfeits.

See our research reports:

Edge Stability in Butcher’s and Kitchen Knives as a Function of Edge Angle and Initial Sharpness

Edge Rolling in High Vanadium Knives Sharpened with Aluminium Oxide versus CBN/Diamond

Best Edge Angle for Ceramic Knives

Effect of Felt and Paper Wheel on Edge Retention

Double-bevel Knives Outperform Single-bevel

Steel Hardness and Ease of Deburring

Effect of Steel Hardness on Edge Retention

Experiments on Knife Steeling

Effect of the Chopping Board Material on Edge Longevity

The Use of Hanging Strop in Knife Sharpening and Maintenance

Does Acidic Food Affect Edge Retention? - by Thomas Larrin

Shaving Edge Retention in High-end Knives

What Edge Angle is good for Supersteels

Heat in Sharpening

|