|

Ranking knife brands by CATRA

Quality & Service

Industrial assessment

Knife rental

Proprietary 7-Carcasses Edge

Equipment we use >

Sharpening procedures

Guarantee

Sharpening resources

Sharpness testing

Edge stability testing

Sharpening Shop

Celebrities, press, exhibitions

Our industrial customers

Contact

Feedback

|

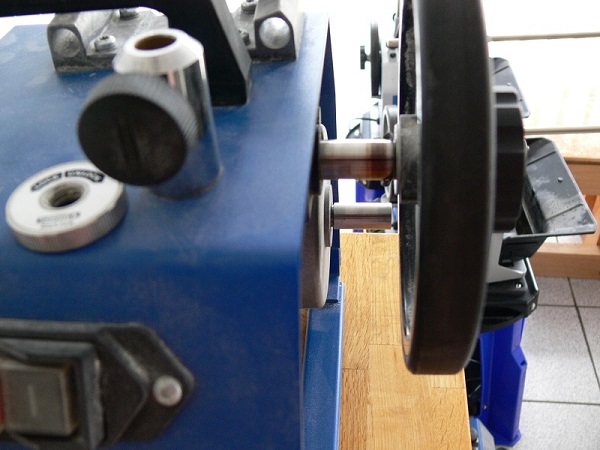

You have heard that CBN and diamond wheels grind better than stone wheels, but that is given that the pressure on the blade is the same. Since the pressure on CBN and diamond wheels must be light, less than on the stone wheel, to see their grinding advantage we need higher RPM. With the RPM-increaser Tormek runs by 40% faster.

In our workshop we have the RPM-increaser on the Tormek with the honing wheels, felt and leather, and on the Tormek with the coarse CBN wheel #80 and # 160. In order to minimize the burr formation, we do NOT increase RPM on Tormek with CBN #400 and #1000.

|

You will need:

Gorilla Clear Epoxy, a disposable cup to mix the epoxy, 5mm skewers, and a rag soaked with turps to remove the excess of epoxy.

Pull out the Tormek drive wheel with the shaft to get access the motor shaft.

Clean the motor shaft and inside the RPM-icreaser with acetone, and let it dry.

Mix the epoxy for good 30-40 seconds.

Dip the skewer in the epoxy and apply plenty of epoxy inside the RPM-increaser insert from both ends.

Push the RPM-increaser onto the motor shaft till the end.

Remove the excess of the epoxy with the rag with turps (turpentine).

Do not disturb for 24 hours to cure.

|

|