|

|

|

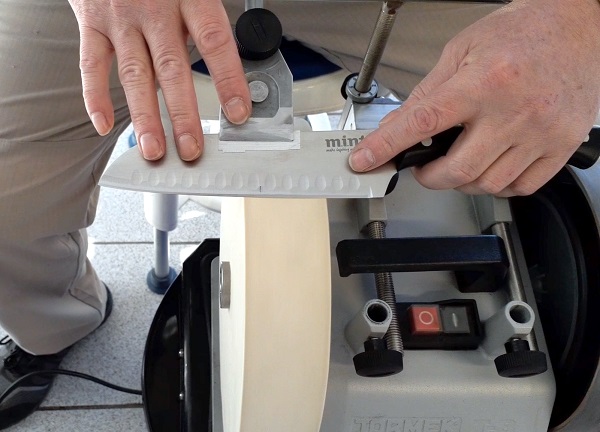

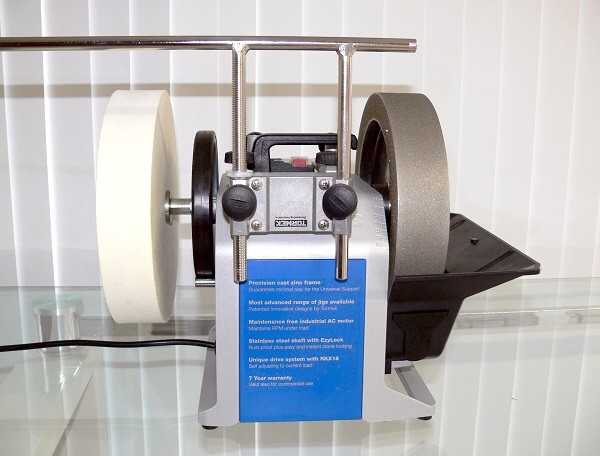

A variant mount on the honing side of the Tormek, using our extension shaft or Tormek LA-120 shaft:

|

Video: Testing rock-hard felt wheel in deburring on Tormek >>

Video: Why Felt >>

For the best results, the felt must be rock-hard - if the felt density is just "hard", "firm" or "medium", it will round the edge and drop sharpness.

We get better sharpness when a honing wheel has diameter close to the grinding wheel, as better matching the profile of the ground edge. Even if the grinding and honing angles are matched perfectly, a smaller honing wheel, like the Tormek leather wheel, will not cover the full height of the bevels ground on the larger wheel - only parts of the bevel will be honed. This is not as obvious at higher edge angles like 15-20 dps, as at lower angles of 13-10 dps.

The felt

wheel is an advanced honing, and fine grinding wheel. Can be used

instead of the expensive Japanese SJ wheel.

Load the felt

wheel with a diamond spray of your choice and you are ready to go.

Felt holds diamond crystals for longer than leather wheels, saving

your expenses on diamonds in deburring and honing hard steels.

One of the advantages of the felt is that thanks to its pliability it deburrs the edge

simultaneously with honing; in this sense, the rock-hard felt stands in-between stone hones and strops.

Another advantage of the diamond-loaded felt over fine stones is that, though rock-hard, the felt is still somewhat compressible, and imparts micro-convexity to the edge apex during honing, strengthening the edge.

Felt holds well diamonds of all sizes, and the rock-hard felt wheel on Tormek is used in duburring knives with diamonds of 6, 3, 1 and 0.5 micron in size. Corresponding diamond spray grits:

6-micron #3,000

3-micron #8,000

1-micron #14,000

0.5-micron #50,000

The diamond suspension must be alcohol-based. Oil-based is acceptable, but works worse.

DO NOT use water-based diamonds on felt.

When not used for a prolonged time, remove the atomizer with the hose from the diamond spray bottle to prevent the hose blockage with dried diamonds.

Rock-hard felt wheel with 1-micron diamonds run on Tormek is the best for removal of the wire edge, feather and foil burrs - you cannot do it on the Tormek leather wheel without rounding the edge, and when you round the edge sharpness drops.

Now the most intriguing fact about felt in deburring:

Felt with diamonds is unique in that it removes the ROOT of the burr. This is where the felt works the best and only felt can do this de-rooting job. We are not aware of any other method that can remove the root of the burr to the clean metal not dulling the edge apex. De-rooting the burr takes the edge to the clean steel - you get the edge clean of all the metal deformed during grinding. This edge has improved retention and stays sharp times longer.

Deburring on the rock-hard felt gives a cleaner edge, stronger micro-convexed apex, higher sharpness, and better edge retention.

In deburring on Tormek, 1 bottle of the 90ml diamond spray lasts for approx. 1,500-2,000 knives.

Re-apply the diamonds after the new wheel stops “dusting”, because some diamonds from the 1st application get lost with the felt dust, then when you see a drop in efficiency, and every time after you clean the wheel of swarf as described in the Maintenance. The drop in efficiency is mostly caused by swarf accumulated on the felt rather than by loss of diamonds.

The 1st bottle of diamond spray empties rather quickly, but then the consumption slows down to 1 bottle per approx. 1,500-2,000 knives.

Remember to

work edge-trailing, with the wheel rotation, using our Frontal Vertical Base. Control the honing angle with our software for Tormek.

Grit can be

changed

Commonly, one felt wheel holds one grit, but if needed you can change it.

To a coarser

grit – no problem, obviously.

To change to

a finer grit, you will have to remove as little as 0.1 mm of the outer layer of felt impregnated with abrasive grains,

using a coarse sandpaper # P80. (Do not use a finer sandpaper, as fine sanding grains may detach and go into the felt.)

MAINTENANCE

When too much swarf accumulates, the felt turns black and efficacy drops. When you see that, sand your felt wheel with a P80 sanding paper on a rectangular wooden block to the clean surface. Re-apply the diamond spray.

Your revived felt wheel will go on like new.

Buy the Felt Wheel for Tormek >

|