|

Carbon

steels

Stainless mainstream (e.g. kitchen & butcher knife)

High-end

and tool steels

Ceramic

Folding

knife

Japanese single-bevel

Cleaver

Convex

blade

Concave & Recurve

blade

Straight

edge, sheepsfoot

Serrated knife

Scissors

Hatchet, tomahawk & axe >

|

Hatchet, tomahawk, carpenter’s & felling axe

Axes out of

our workshop are shaving sharp.

"Convex" in this procedure refers to the blade shape and edge line, not the edge profile. Obviously, it is impossible to grind an edge of convex profile on a wheel - the wheel will always give a somewhat concave profile. Grinding on the wheel is OK for hatchets, carpenter's axe and felling axe, but not good for the splitting axe.

Measure the

existing edge angle with AngleMaster, if ordered to reproduce.

Our

default for hatchets, tomahawks & carpenter's axes is 25 degrees included, but you can specify any edge angle.

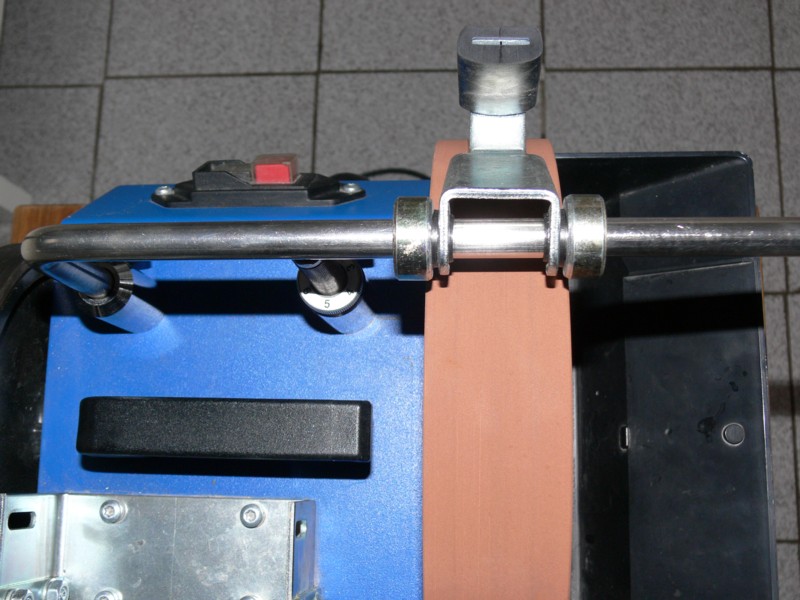

Put on the Universal

Support a locking collar, axe jig, and another locking collar.

Center the

jig over the stone, and fix in place with the collars.

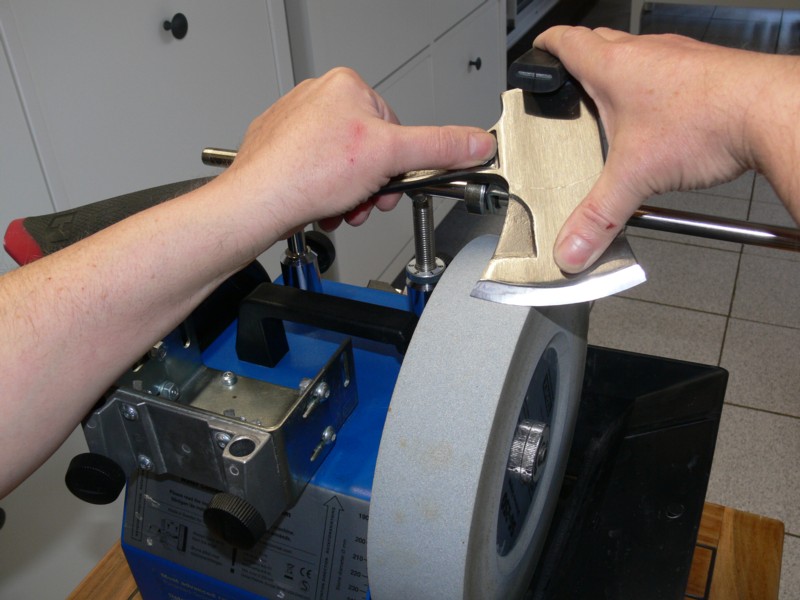

Center the

hatchet in the jig - the edge center, not the butt.

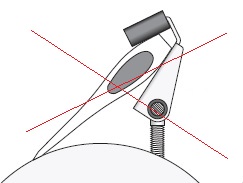

The hatchet

should sit in the axe jig with its lower surface flat to the lower jig

jaw (not as shown in the Tormek manual).

Set the

grinding angle using AngleMaster.

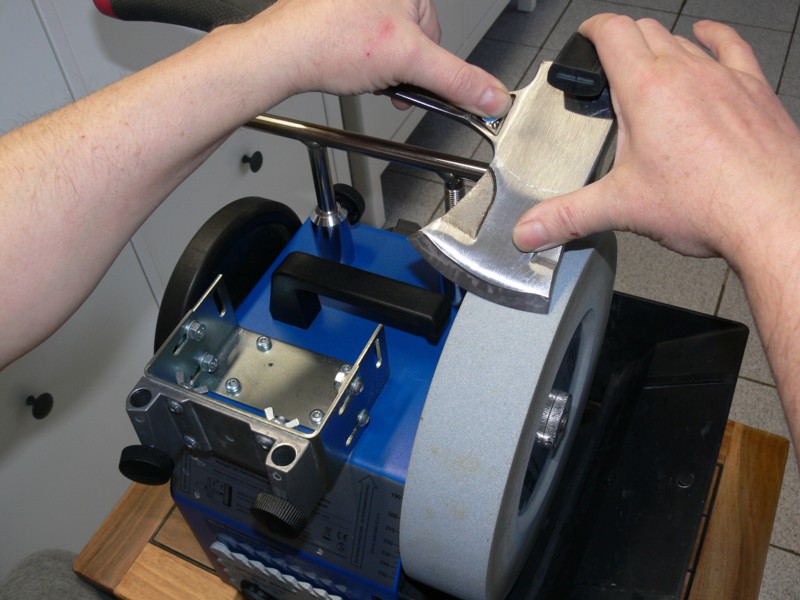

Shape the

bevel on an Aluminium Oxide wheel SG-250, grit 220.

Pressing

the hatchet blade flat to the lower jig jaw and down to the stone, grind

with pendulum-like passes by moving its handle with another hand so that

the convex of the edge passes along the imaginary line across the edge through

the farthest point of the blade apex; maintain the edge contact with the

stone by raising or lowering the handle.

Having ground

the bevel, measure the actual edge angle to see if the angle is

the desired one. If you need a more acute edge angle, lower down the US

support till you see a gap between the stone and the edge, and continue

grinding.

Change to

the 10” Japanese wheel, grit 1200 (JIS 800).

Adjust the US

height as needed to continue at the same angle.

Grind as

above.

Continue

alternating sides of the blade, doing 2 gliding passes on each side x 2,

and then a single gliding pass.

Finish by stropping.

Test

sharpness.

|

Measure

the existing edge angle with AngleMaster, if ordered to reproduce.

Our default for hatchets, tomahawks & carpenter's axes is 25 degrees included, but you can specify any edge angle.

|

|

|

Put on

the Universal Support a locking collar, axe jig, and another locking

collar.

Center

the jig over the stone, and fix in place with the collars.

|

|

|

Center the

hatchet in the jig - the blade center, not the butt.

The

hatchet should sit in the axe jig with its lower surface flat to the

lower jig jaw (not as shown in the Tormek manual).

Set the

grinding angle using AngleMaster.

|

|

|

Shape the

bevel on an Aluminium Oxide wheel SG-250, grit 220.

Pressing

the hatchet blade flat to the lower jig jaw and down to the stone,

grind with pendulum-like passes by moving its handle with another hand

so that the convex of the edge passes along the imaginary line across the edge

through the farthest point of the blade apex; maintain the edge contact

with the stone by raising or lowering the handle.

Having ground

the bevel, measure the edge angle to see if the actual angle

is the desired one. If you need a more acute edge angle, lower down the

US support till you see a gap between the stone and the edge, and

continue grinding.

|

|

|

Change to

the 10” Japanese wheel, grit 1200 (JIS 800).

Adjust the US height as needed to continue at the same angle.

Grind as

above.

Continue

alternating sides of the blade, doing 2 gliding passes on each side x

2, and then a single gliding pass.

|

|

|

Finish by

stropping.

|

|

|

Test

sharpness.

|

|

|