|

Carbon

steels

Stainless mainstream (e.g. kitchen & butcher knife)

High-end and tool steels

Ceramic

Folding knife

Japanese single-bevel >

Cleaver

Convex blade

Concave & Recurve blade

Straight edge, sheepsfoot

Serrated knife

Scissors

Hatchet, tomahawk & axe

|

Japanese single-bevel blade

Video >>

Measure the

existing edge angle with a laser protractor, if ordered to reproduce.

(Our

default for quality high-carbon Japanese knives is 16 degrees; lower-end knives we sharpen at 20 degrees.)

Clamp in a knife jig.

Using our Frontal Vertical Base at the front of the Tormek, position the knife so that the backside edge rests on the wheel with the knife jig parallel to the top of your Tormek.

Polish the flat back on the Japanese wheel SJ-250 horizontally - initially do just 2 passes.

You will get a narrow polished strip all along the edge; don't bother if it is not ideally uniform at this step.

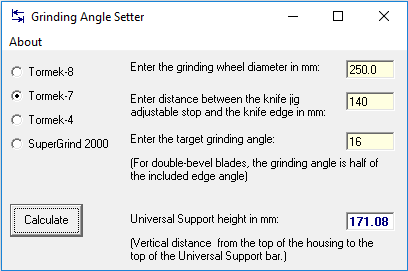

Set the

grinding angle using our computer software "Grinding Angle Setter".

Grind the bevel side into the edge on

a coarse wheel, e.g. SG-250 grit 220, or diamond wheel DC-250, or a CBN wheel.

Using our Frontal Vertical Base at the front of the Tormek, polish the flat back on the Japanese wheel SJ-250 horizontally; usually 1 pass is OK.

With the help of our computer software "Grinding Angle Setter" calculate the Universal Support height

for the next grinding wheel.

Grind the bevel side into the edge on a fine wheel, e.g. a 10” Japanese wheel JIS 800, or a diamond or CBN wheel #1000-1200.

Typically it takes 2-4 passes.

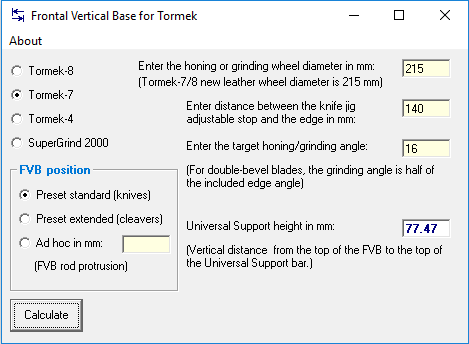

With the

help of our software for the Frontal Vertical Base calculate the Universal Support height for honing on the leather wheel.

Hone the beveled side at the edge angle on the Tormek leather wheel with the Tormek honing paste; typically 2-4 passes.

Using the Frontal Vertical Base, deburr the flat back on the Japanese wheel SJ-250 by 1 horizontal pass.

Finish on a hanging strop by 6-10 passes alternating sides.

Test

sharpness.

|

Measure

the existing edge angle with a laser protractor, if ordered to

reproduce.

(Our

default for quality high-carbon Japanese knives is 16 degrees; lower-end knives we sharpen at 20 degrees.)

|

|

|

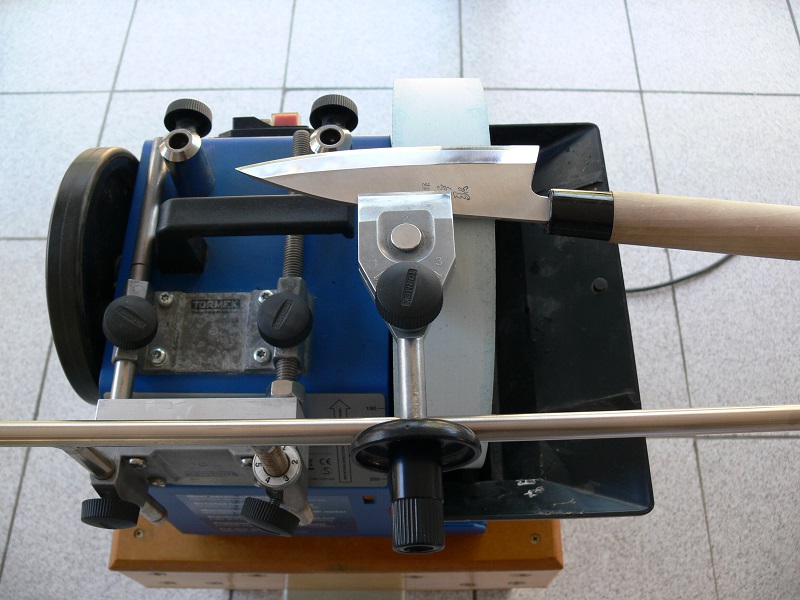

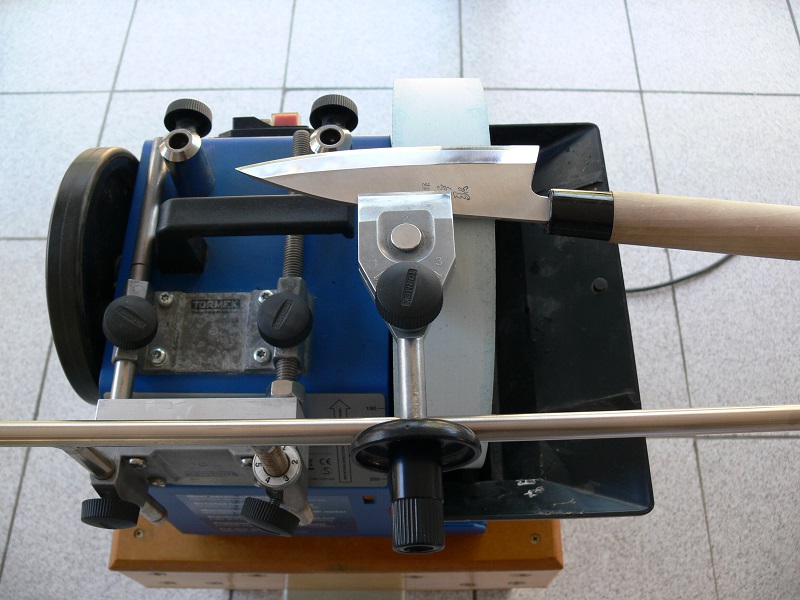

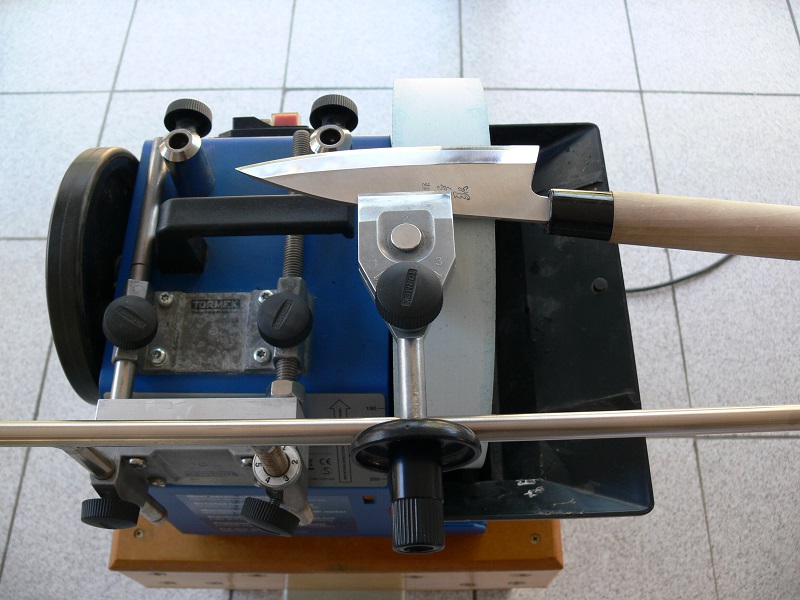

Clamp in a knife jig.

Using our Frontal Vertical Base at the front of the Tormek, position the knife so that the backside edge rests on the wheel with the knife jig parallel to the top of your Tormek.

Polish the flat back on the Japanese wheel SJ-250 horizontally - initially do just 2 passes.

You will get a narrow polished strip all along the edge; don't bother if it is not ideally uniform at this step.

|

|

|

Set the

grinding angle using our computer software "Grinding Angle Setter".

|

Jig-Support-Wheel

relations are calculated by computer scripts, and set with 0.1 degree

accuracy.

|

|

Grind the bevel side into the edge on

a coarse wheel, e.g. SG-250 grit 220, or diamond wheel DC-250, or a CBN wheel.

|

|

|

Using our Frontal Vertical Base at the front of the Tormek, polish the flat back on the Japanese wheel SJ-250 horizontally; usually 1 pass is OK.

|

|

|

With the help of our computer software "Grinding Angle Setter" calculate the Universal Support height

for the next grinding wheel.

Grind the bevel side into the edge on a fine wheel, e.g. a 10” Japanese wheel JIS 800, or a diamond or CBN wheel #1000-1200.

Typically it takes 2-4 passes.

|

|

|

With the

help of our software for the Frontal Vertical Base calculate the Universal Support height for honing on the leather wheel.

|

|

|

Hone the beveled side at the edge angle on the Tormek leather wheel with the Tormek honing paste; typically 2-4 passes.

|

|

|

Using the Frontal Vertical Base, deburr the flat back on the Japanese wheel SJ-250 by 1 horizontal pass.

|

|

|

Finish on a hanging strop by 6-10 passes alternating sides.

|

|

|

Test

sharpness

|

|

|