|

Carbon

steels

Stainless mainstream (e.g. kitchen & butcher knife)

High-end

and tool steels

Ceramic >

Folding

knife

Japanese single-bevel

Cleaver

Convex

blade

Concave & Recurve

blade

Straight

edge, sheepsfoot

Serrated knife

Scissors

Hatchet,

tomahawk & axe

|

Ceramic

Ceramic knives are sharpened with CBN or diamond wheels.

What we know of steel sharpening cannot be extrapolated to ceramic blades.

Sharpenging through micro-chipping is the most plausible mechanism - instead of actually cutting the ceramic, diamond/CBN particles remove material by chipping it away.

Unlike steel blades, where you get a well cutting edge off the grit #400, and a shaving edge off #1000, the ceramic edge will be blunt after #400, and hardly cutting after #1000 - it has to be sharpened further with the finer 10 micron, 5-6 micron and 2.5 micron diamonds to get it sharp.

The BESS scores we get in the process of sharpening ceramic correlate with the abrasive grit more than the steel:

CBN#400 gives 500-700 BESS - CBN#600 gives 500 BESS - CBN#1000 gives 280-400 BESS - 5 micron diamond 105-120 BESS - and 0.5 micron diamond 55-90 BESS.

A well sharpened ceramic knife typically has sharpness of around 200 BESS.

Our

default for ceramic knives is 30 degrees included - see our research on the best edge angle for ceramic knives

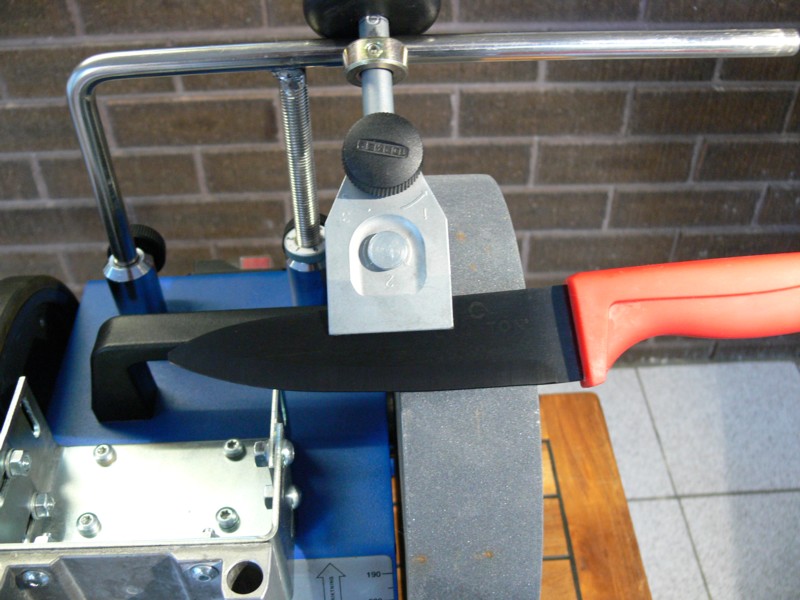

Clamp in a jig

matching the blade thickness.

Set the

grinding angle using our computer software.

Shape the bevel

on a coarse CBN/Diamond wheel grit 160 or 200.

Sharpen on

a 10” CBN wheel, grit 400 or 600.

Continue on

a 10” CBN wheel, grit 1000.

Read more>>

Continue to

controlled-angle honing on a 10” paper wheel with 10 micron, 5 micron and then 2.5 micron diamond paste.

Finish with

controlled-angle honing on a 10” paper wheel with a mix of 0.5/0.25

micron diamond paste.

Test

sharpness.

|

Measure

the existing edge angle with a laser protractor, if ordered to

reproduce.

|

|

|

Clamp in

a jig matching the blade thickness.

|

|

|

Set the grinding

angle using our computer software.

|

Jig-Support-Wheel

relations are calculated by computer scripts, and set with 0.1 degree

accuracy.

|

|

Shape the

bevel on a coarse CBN/Diamond wheel grit 160 or 200.

|

|

|

Sharpen

on a 10” CBN wheel, grit 400 or 600.

Read more>>

|

|

|

Continue

on a 10” CBN wheel, grit 1000.

|

|

|

Continue

to controlled-angle honing on a 10” paper wheel with 10 micron, 5 micron and then 2.5 micron diamond

paste.

|

|

|

Finish with

controlled-angle honing on a 10” paper wheel with a mix of 0.5/0.25 micron

diamond paste.

|

|

|

Test

sharpness

|

|

|