Grinding Software Testing

Knives and blades tested:

Thin behind the edge double-bevel knives two

knives 0.5 mm and 1.2 mm behind the edge (thickness at the spine 2 mm and 3.7 mm);

Thick behind the edge double-bevel knives - two

knives 1.6 mm and 2.5 mm behind the edge (thickness at the spine 4.5 mm and 6.5

mm);

Single-bevel knives two knives 0.8 mm and 1.8 mm behind the edge (thickness

at the spine 2.5mm and 3 mm).

2mm double-bevel steel plate - 2 mm behind the edge.

3mm double-bevel steel plate - 3 mm behind the edge.

Thickness behind the edge in knives

is measured the following way:

when re-sharpening close to the original edge angle - at the edge bevel;

when re-profiling to a lower angle or sharpening a grossly dull knife - within

3-5 mm from the edge bevel.

Thickness behind the edge in the plate is constant and the same as the

thickness of the plate.

The actual knives and blades used in the testing are shown below:

3mm double-bevel plate - 3 mm behind the edge

|

|

|

Grinding wheels used in the test:

Coarse #80, Medium #400 and Fine #1000. These particular

grinding wheels differ in diameter by 4 mm, and our software is used to match

the grinding angle.

Tormek machines used in the test:

We used in the testing two Tormek T-7, two Tormek T-8, and one Tormek T-4 machines, 5 total.

Laser protractor used in edge angle measurements:

CATRA Laser Knife Edge Protractor, accuracy ±0.2 degree.

Sharpness tester:

PT50B

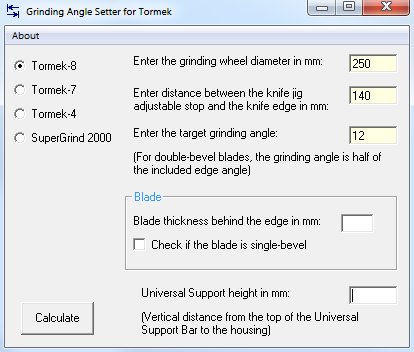

Applet 1 - Grinding Angle Setter for Tormek

Angles are given in degrees per side.

MODE 1: Sharpen a knife

|

Target angle in the calculation |

10° |

12° |

14° |

16° |

18° |

20° |

|

0.5mm behind the edge double-bevel knife ground angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

1.2mm behind the edge double-bevel knife ground angle |

|

12° |

|

16° |

|

20° |

|

1.6-2.5mm behind the edge double-bevel knives ground angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

Target angle in the calculation |

16° |

18° |

20° |

|

Single-bevel knife ground angle |

16° |

18° |

20° |

MODE 2: Grind a 3mm double-bevel plate blade

|

Target angle in the calculation |

12° |

14° |

16° |

18° |

20° |

|

3mm double-bevel plate ground angle |

12° |

14° |

16° |

18° |

20° |

MODE 3: Re-profile a knife to a lower angle

|

Original edge angle |

20° |

|

Target angle in the calculation |

12° |

|

Thin double-bevel knife ground angle |

12° |

|

Thick double-bevel knife ground angle |

12° |

|

Original edge angle |

20° |

|

Target angle in the calculation |

16° |

|

Single-bevel knife ground angle |

16° |

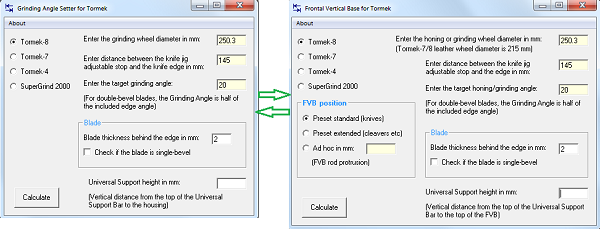

Applet 2 Frontal Vertical Base for Tormek

Angles are given in degrees per side.

MODE 1: Re-sharpen at the original edge angle

|

Target angle in the calculation |

10° |

12° |

14° |

16° |

18° |

20° |

|

0.5 mm behind the edge double-bevel knife ground angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

1.2 mm behind the edge double-bevel knife ground angle |

|

12° |

|

16° |

|

20° |

|

1.6-2.5mm behind the edge double-bevel knives ground angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

Target angle in the calculation |

16° |

18° |

20° |

|

Single-bevel knife ground angle |

16° |

18° |

20° |

MODE2: Tormek Leather Wheel honing

Our software is used to match the ground angle to the honing angle.

Check the ground and honing angle match by the marker method and sharpness tester

|

Actual edge angle |

12° |

16° |

18° |

20° |

|

Thin double-bevel knife |

match |

match |

match |

match |

|

Thick double-bevel knife |

match |

match |

match |

match |

|

Single-bevel knife |

|

match |

match |

match |

The BESS Sharpness Tester PT50 showed 60-80 BES for the 12° and 16° edge

honed with the Tormek honing paste at the ground angle, and 150 BESS for the

20° edge.

This is in line with the sharpness reading weve shown earlier for knife steels:

- a burrless 12 dps edge is scoring 50-70 BESS, while the residual burr will

show over 100 BESS;

- a burrless 14-16 dps edge is scoring 70-90 BESS, while the residual burr will

show over 120 BESS;

- a burrless 20 dps edge is scoring 80-150 BESS, while the residual burr will

show over 150 BESS.

Deburr serrated knives

Sharpness under 100 BESS in the serrations.

Cross-check between the Grinding Angle Setter and Frontal Vertical Base

Grind a 2mm double-bevel flat blade

Angles are given in degrees per side.

|

Target angle in the calculation |

10° |

11° |

12° |

13° |

14° |

15° |

16° |

17° |

18° |

19° |

20° |

|

Grinding Angle Setter ground angle |

10° |

|

12° |

|

14° |

|

16° |

|

18° |

|

20° |

|

Frontal Vertical Base ground angle |

|

11° |

|

13° |

|

15° |

|

17° |

|

19° |

|

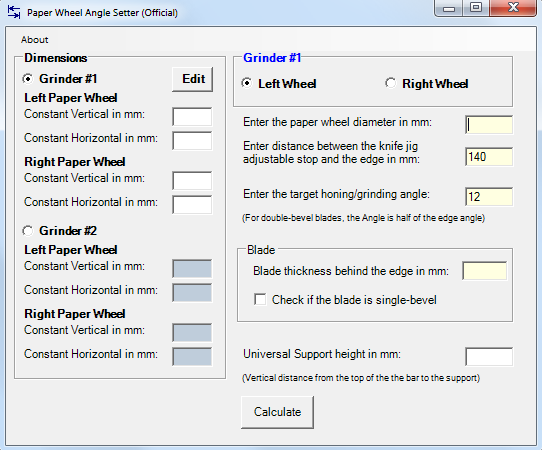

Applet 3

Paper Wheel Angle Setter

Testing done on:

1 x Gritted paper wheel, diameter 260mm.

3 x Slotted honing paper wheels: diameter 256mm, 251mm and 247mm.

3 x 8 Buffers & Grinders running 10 paper wheels.

GRITTED PAPER WHEEL GRINDING

Check the edge angle ground on a gritted paper wheel by the CATRA laser

protractor.

|

TARGET edge angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

Thin double-bevel knife |

OK |

OK |

OK |

OK |

OK |

OK |

|

Thick double-bevel knife |

OK |

OK |

OK |

OK |

OK |

OK |

|

Single-bevel knife |

|

|

|

OK |

OK |

OK |

SLOTTED PAPER WHEEL HONING

Check the match of the edge angle ground on Tormek or gritted paper wheel to

the honing angle on slotted paper wheel by the marker method and sharpness

tester.

|

ACTUAL edge angle |

10° |

12° |

14° |

16° |

18° |

20° |

|

Thin double-bevel knife |

match |

match |

match |

match |

match |

match |

|

Thick double-bevel knife |

match |

match |

match |

match |

match |

match |

|

Single-bevel knife |

|

|

|

match |

match |

match |

BESS Sharpness tester shows 50-55 BESS for a 12 dps edge, 70 BESS for a 15 dps edge, and 130 BESS for 20 dps edge honed on paper wheels.

This is in line with the sharpness reading for knife steels weve explained above, and better than what we see in edges honed on Tormek leather wheel.

Copyright 2019 by Knife Grinders, Australia